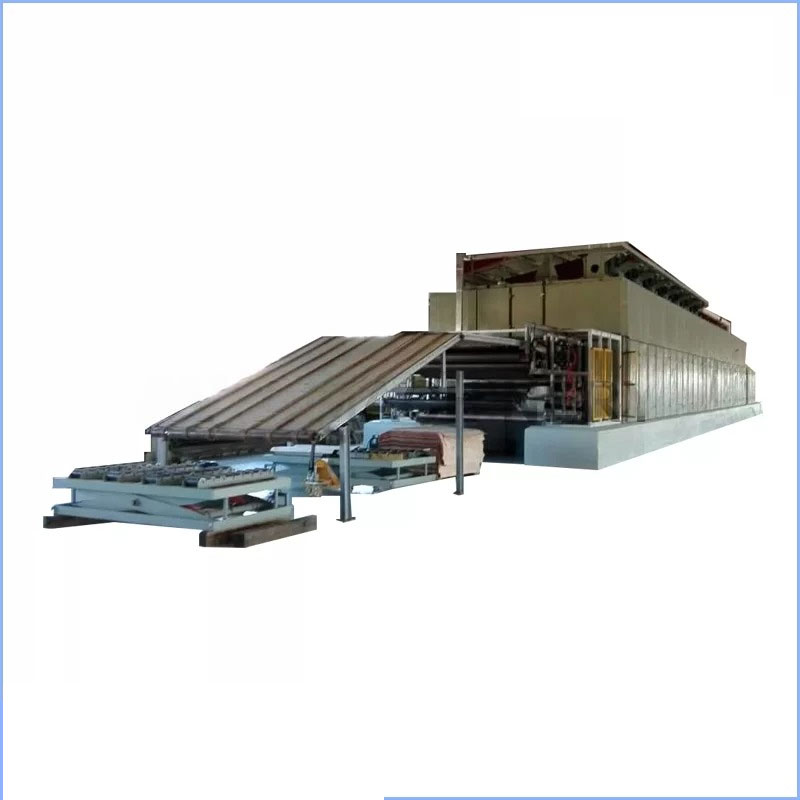

1) One machine multi-purpose, widely used

2) The product quality is good, the dehydration color is good, the internal quality is stable.

3) Drying efficiency, drying time is short, single drying quantity is large.

4) Long storage period, improve the qualified rate of products, reduce the rate of defective products.